APPLICATION/END USE

Section outline

-

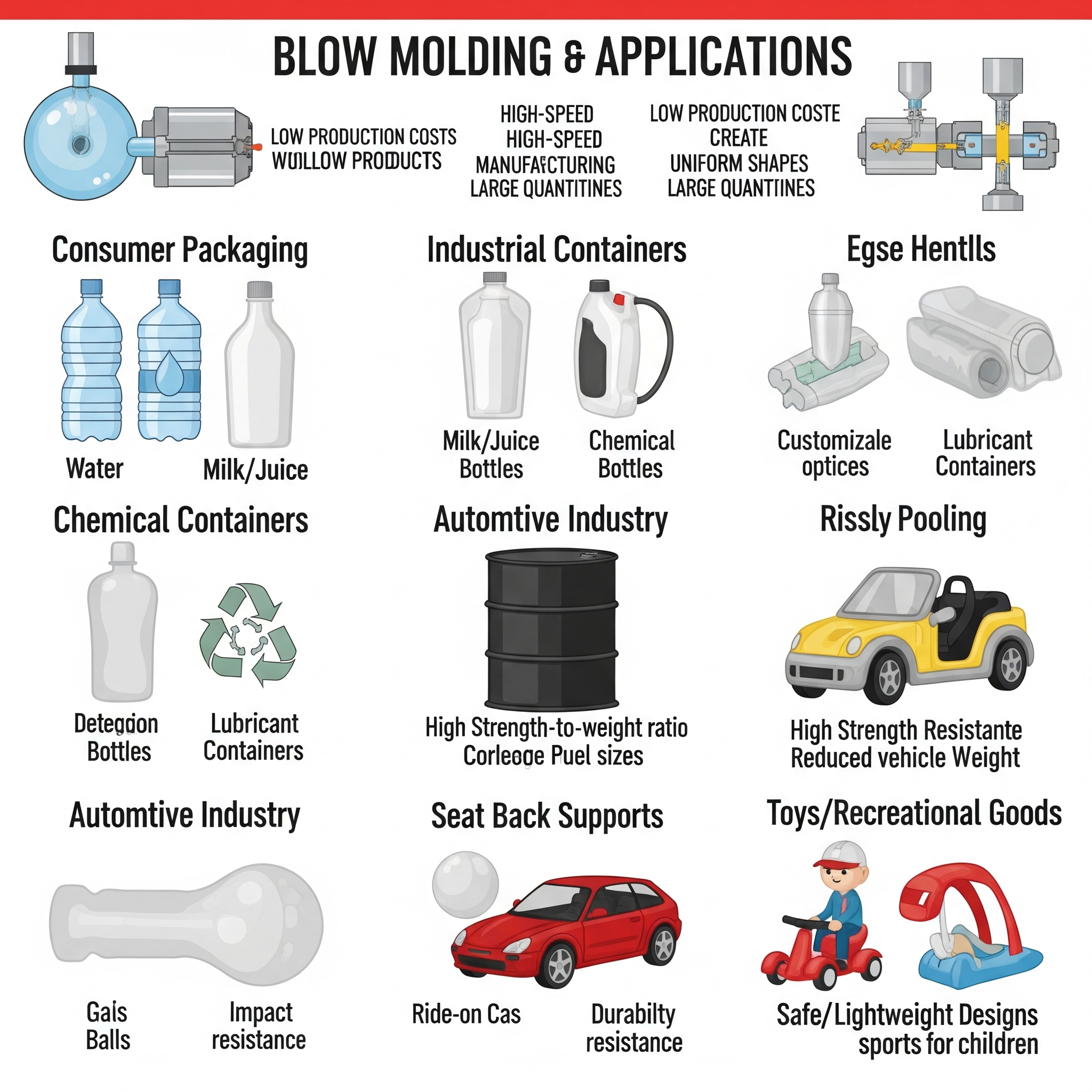

Blow moulding is widely used to manufacture hollow plastic products. It offers low production costs, high-speed manufacturing, and the ability to create uniform shapes in large quantities.

Blow moulding is widely used to manufacture hollow plastic products. It offers low production costs, high-speed manufacturing, and the ability to create uniform shapes in large quantities.

🏠 1. Consumer Packaging

Products:

-

Water bottles (PET bottles)

-

Milk and juice bottles

-

Shampoo and conditioner bottles

-

Detergent and cleaning product containers

-

Lotion, soap, and cosmetic bottles

Why Used:

-

Lightweight, easy to handle

-

Customizable shapes and sizes

-

Recyclable material options

🏭 2. Industrial Containers

Products:

-

Chemical drums and storage tanks

-

Fuel tanks (for vehicles or generators)

-

Lubricant and oil containers

Why Used:

-

High strength-to-weight ratio

-

Resistant to corrosion

-

Suitable for hazardous or chemical contents

🚗 3. Automotive Industry

Products:

-

Air ducts

-

Windshield washer fluid bottles

-

Fuel tanks

-

Seat back supports (in some designs)

Why Used:

-

Reduced vehicle weight (improves fuel efficiency)

-

Durable and impact-resistant

-

Can be produced in complex shapes

🧸 4. Toys and Recreational Goods

Products:

-

Hollow plastic toys (e.g., balls, ride-on cars)

-

Inflatable or light plastic sporting equipment

Why Used:

-

Safe and lightweight for children

-

Economical for mass production

-

Easy to mold into fun, colorful shapes

-