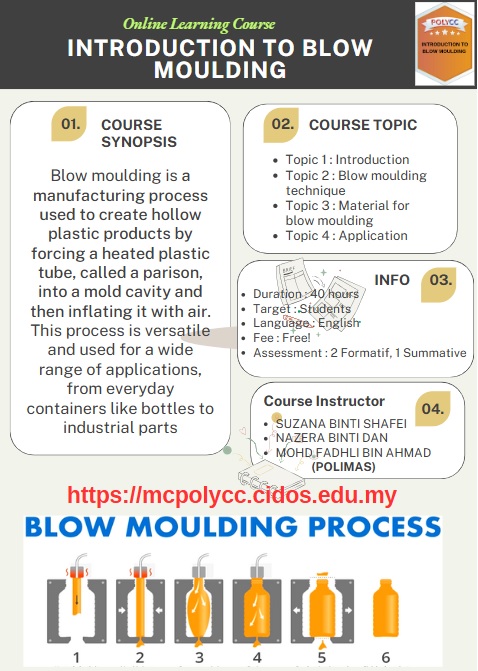

INTRODUCTION TO BLOW MOULDING

Section outline

-

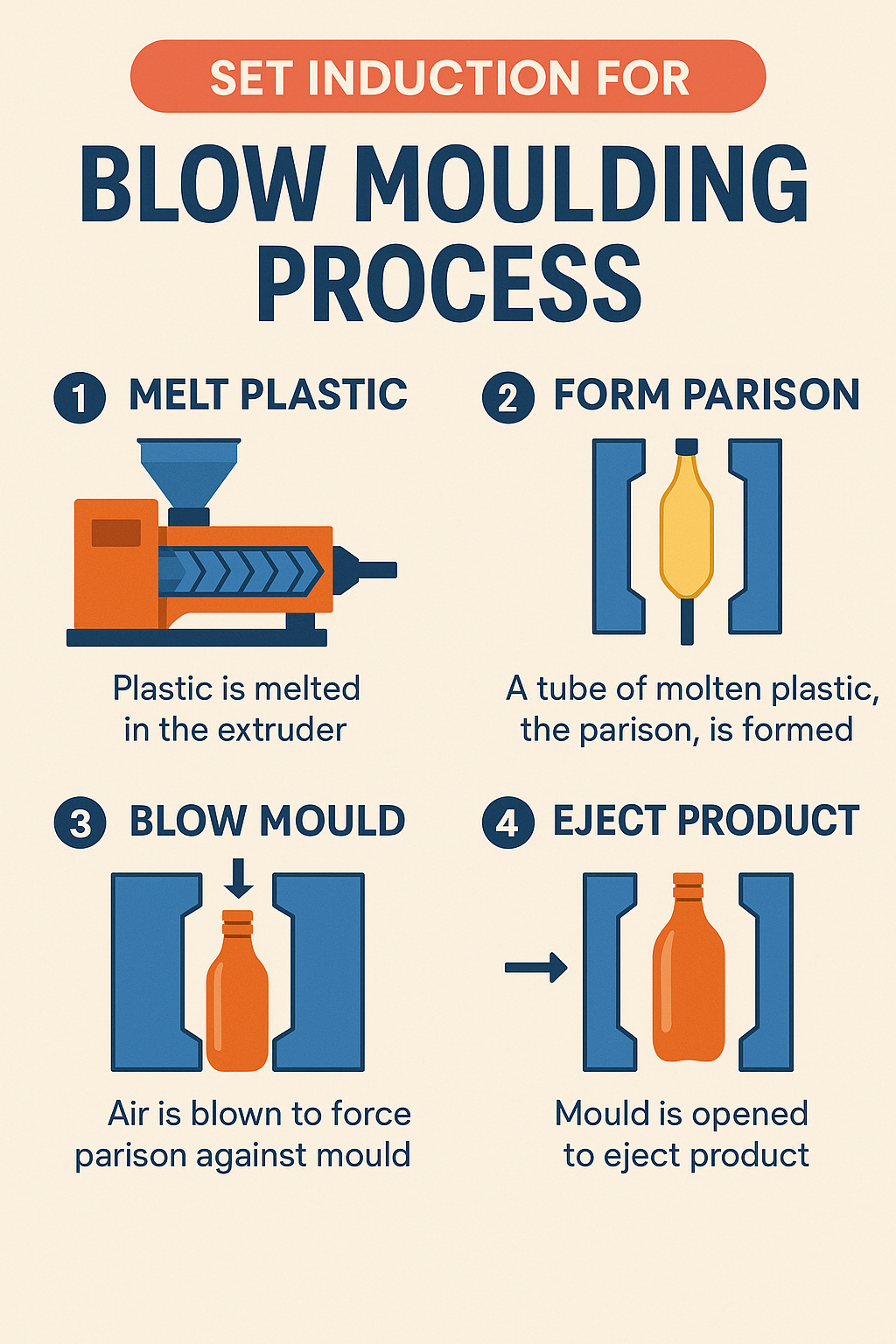

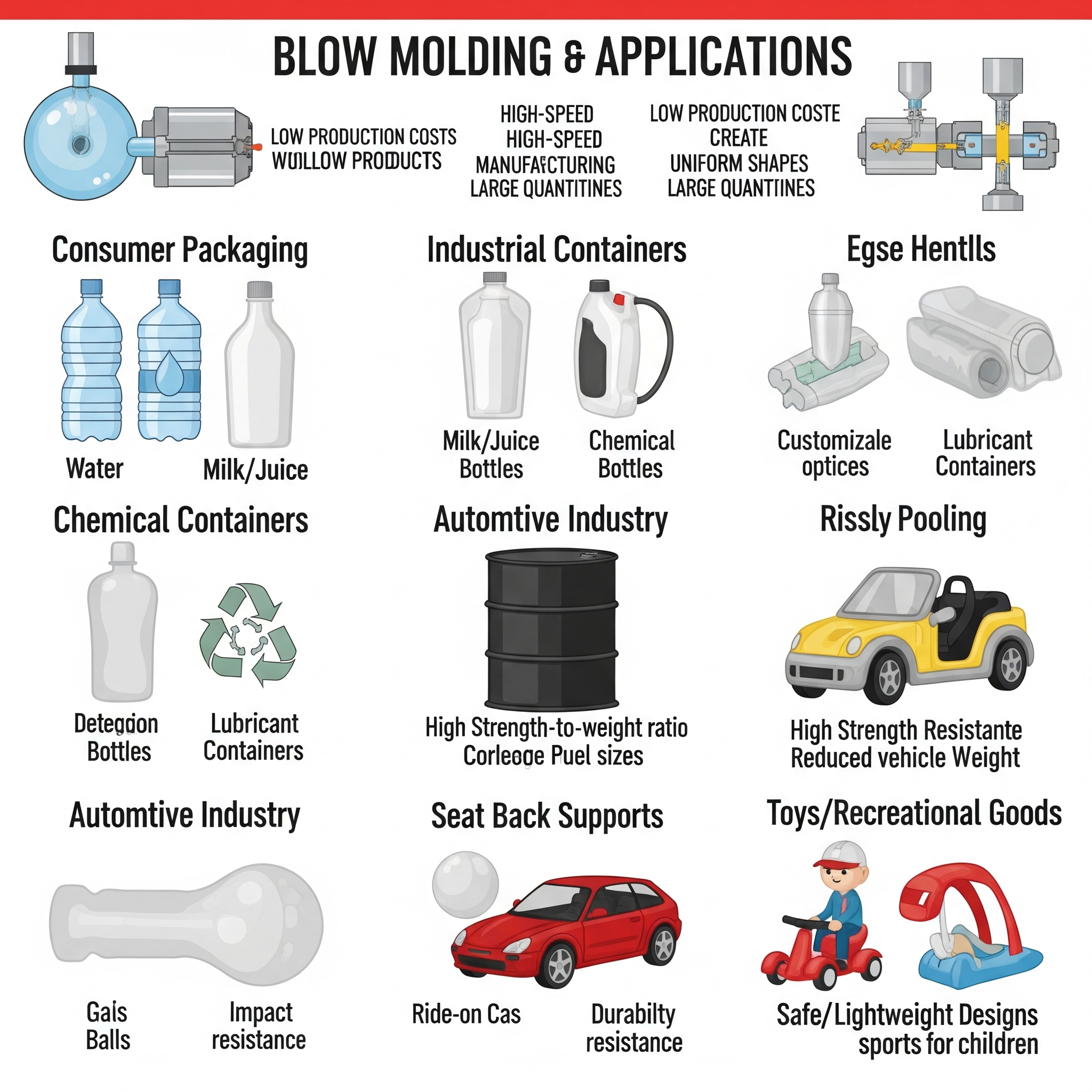

Blow moulding is widely used to manufacture hollow plastic products. It offers low production costs, high-speed manufacturing, and the ability to create uniform shapes in large quantities.

Blow moulding is widely used to manufacture hollow plastic products. It offers low production costs, high-speed manufacturing, and the ability to create uniform shapes in large quantities.

🏠 1. Consumer Packaging

Products:

-

Water bottles (PET bottles)

-

Milk and juice bottles

-

Shampoo and conditioner bottles

-

Detergent and cleaning product containers

-

Lotion, soap, and cosmetic bottles

Why Used:

-

Lightweight, easy to handle

-

Customizable shapes and sizes

-

Recyclable material options

🏭 2. Industrial Containers

Products:

-

Chemical drums and storage tanks

-

Fuel tanks (for vehicles or generators)

-

Lubricant and oil containers

Why Used:

-

High strength-to-weight ratio

-

Resistant to corrosion

-

Suitable for hazardous or chemical contents

🚗 3. Automotive Industry

Products:

-

Air ducts

-

Windshield washer fluid bottles

-

Fuel tanks

-

Seat back supports (in some designs)

Why Used:

-

Reduced vehicle weight (improves fuel efficiency)

-

Durable and impact-resistant

-

Can be produced in complex shapes

🧸 4. Toys and Recreational Goods

Products:

-

Hollow plastic toys (e.g., balls, ride-on cars)

-

Inflatable or light plastic sporting equipment

Why Used:

-

Safe and lightweight for children

-

Economical for mass production

-

Easy to mold into fun, colorful shapes

-

-

Blow moulding is an efficient and versatile manufacturing process used to create hollow plastic products across many industries. From everyday household items like bottles and containers to industrial components, blow moulding continues to be a practical solution for creating durable, cost-effective products. While it has some limitations, its benefits make it a go-to choice for many manufacturers.

-

- Lee, Norman C. Understanding Blow Molding.

- Lee, Norman C. Plastic Blow Molding Handbook.

- Rosato, Dominick V. Blow Molding Handbook.

- Lee, Norman C. Blow Molding Design Guide.

- Yam, K. L. Encyclopedia of Packaging Technology.

- Ottmar Brandau. Stretch Blow Molding.

- Rosato, Dominick V., et al. Blow Molding Handbook: Technology, Performance, Markets, Economics: The Complete Blow Molding Operation.