2.0 INTRODUCTION TO MAINTENANCE ENGINEERING AND MANAGEMENT IN MANUFACTURING INDUSTRY

Section outline

-

INTRODUCTION

-

INTRODUCTION

Manufacturing has played a crucial role in human civilization, transitioning from handcrafted products to the highly automated procedures that characterize modern manufacturing. Innovations in technology have greatly increased production, efficiency, and quality since the Industrial Revolution. Computer Numerical Control (CNC) machines are one example of this innovation, which has transformed industry by making automated and extremely accurate machining possible. CNC machines reduce human error and increase production consistency by using pre-programmed software to operate tools and equipment. Because these machines can perform complicated cutting, drilling, milling, and turning operations with great accuracy and efficiency, they are extensively utilized in sectors including automotive, aerospace, electronics, and manufacturing of metals. CNC technology, combined with advancements like artificial intelligence (AI) and the Internet of Things (IoT), is transforming manufacturing through increased efficiency, reduced waste, and improved product quality. Even with these developments, maintenance is still necessary to guarantee the effective and reliable operation of production machines, especially CNC machines.

In manufacturing, maintenance can be divided into four main categories: predictive maintenance, which uses data and monitoring systems to predict possible problems before they occur; corrective maintenance, which fixes minor issues before they become major failures; breakdown maintenance, which deals with sudden equipment failures that require immediate repairs; and preventive maintenance, which involves periodic checks and servicing to avoid unexpected failures. Preventive maintenance in CNC machining involves inspecting cutting tools to stop wear and tear, lubricating moving parts, and cleaning machine components. IoT sensors may be used for predictive maintenance, which tracks machine performance, identifies deviations, and plans repairs before breakdowns happen. These tactics not only increase the lifespan of equipment but also improve operational effectiveness and decrease production downtime.

Basic maintenance is important for maintaining worker safety and production efficiency. IoT sensors, for example, are used in predictive maintenance in the automobile sector to track engine performance and identify any problems before they affect output. Preventive maintenance keeps food processing equipment hygienic and operational in order to meet hygienic standards. Corrective maintenance takes care of little defects in electronics production before they cause large losses in product value. For accuracy and consistency, CNC machines in the metal fabrication industry need to have their calibration and tool replacements done on a regular basis. By putting these maintenance techniques into practice, producers may minimize downtime, uphold high standards of quality, and maximize overall production efficiency, providing reliable and effortless operations.

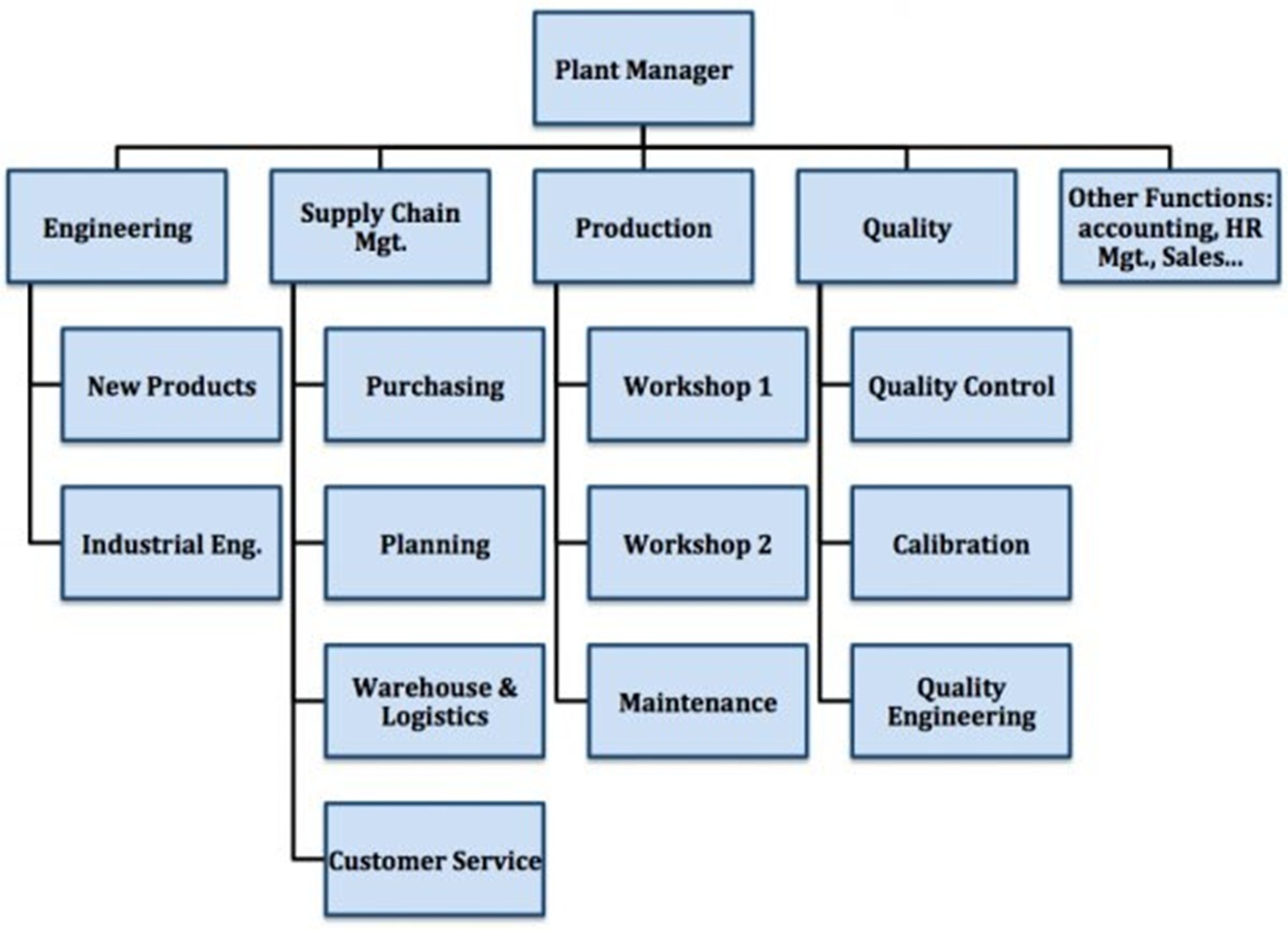

The chart below shows the organizational chart in the industry. The manufacturing industry's organizational structure is crucial for good coordination, output, and efficiency. Production managers are responsible for monitoring operations, manufacturing engineers optimize processes, and quality control specialists guarantee product standards. Supply chain managers manage logistics, maintenance technicians keep up with machinery, and machine operators operate machines. Ensuring the industrial facility operates in a productive and efficient manner is the duty of maintenance management (Mobley, 2002). A well-designed system minimizes downtime, improves quality, and guarantees safety; a neglected system causes delays, breakdowns of equipment, and more costs. To maintain industrial efficiency and competitiveness, effective organization is important.

Figure 1: Organization Chart

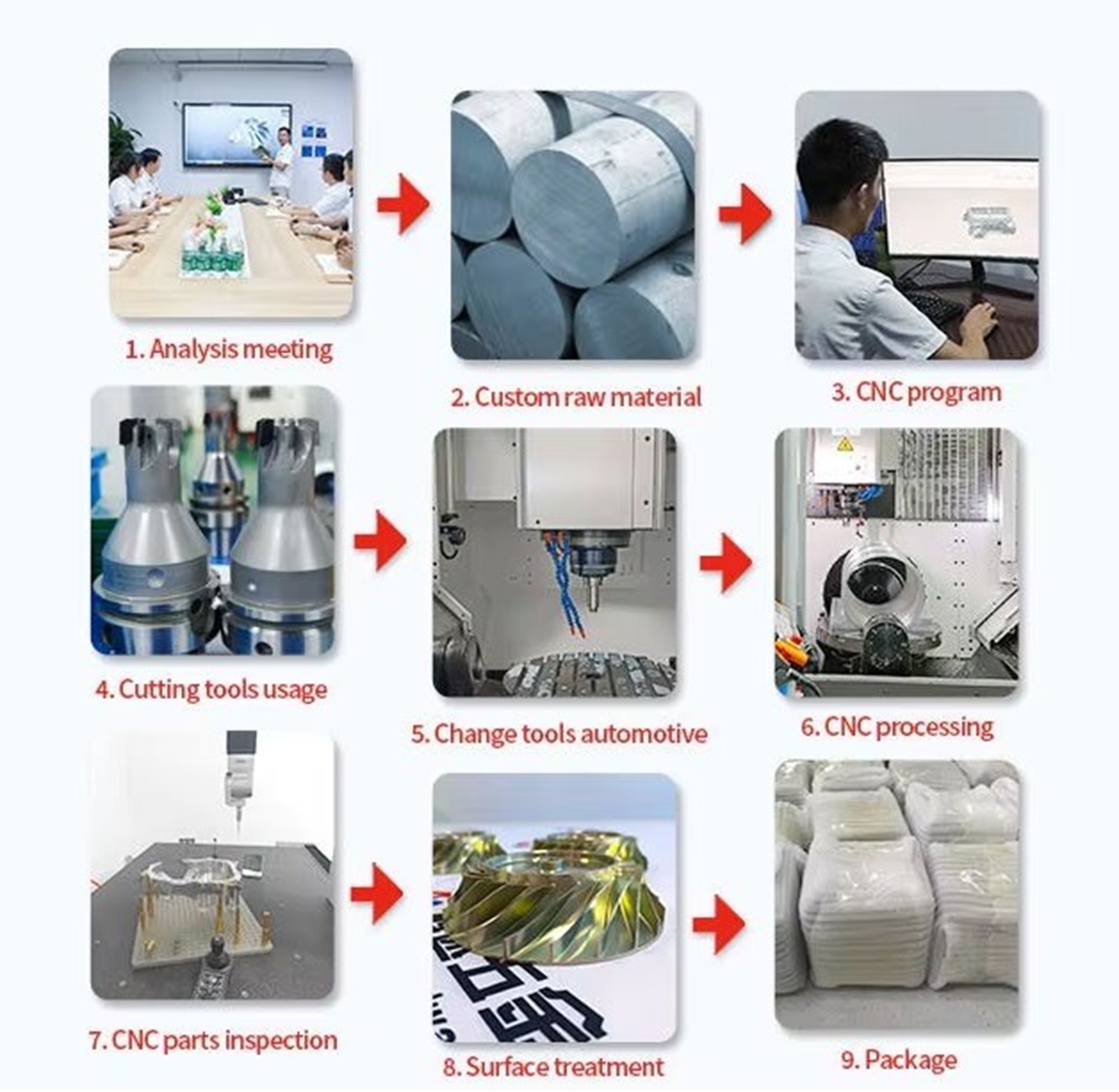

The manufacturing system shown in the illustration below follows a systematic CNC machining procedure to guarantee accuracy, effectiveness, and quality. Finding specific raw materials appropriate for production occurs after an analysis meeting to go over project requirements. Then, to manage machining processes, CNC software is created. After that, the right cutting tools are made, and automatic tool changes will be set in place. High-precision machining is done at the CNC processing step, and accuracy is verified by inspecting the CNC components. After surface treatment improves finishing and durability, the finished items are ultimately packed for shipping. In modern industrial applications, this systematic strategy optimizes production efficiency, quality control, and resource use by integrating new manufacturing processes.

Figure 2: Structured CNC Machining Process in Manufacturing Industry

-

-