3.0 EFFECTIVE MANUFACTURING SCHEDULING FOR CNC MAINTENANCE AND PRODUCTIVITY

Section outline

-

-

EFFECTIVE MANUFACTURING SCHEDULING FOR CNC MAINTENANCE AND PRODUCTIVITY

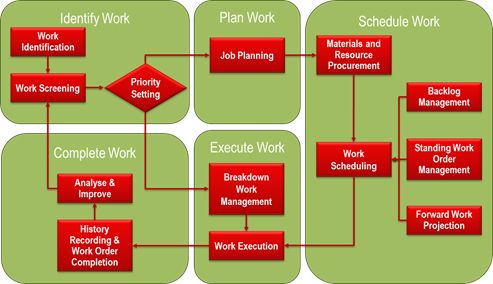

In order to guarantee effective coordination of production and maintenance, manufacturing scheduling is required. So as to reduce downtime and improve overall equipment effectiveness (OEE), manufacturers should plan maintenance tasks, schedule production operations, and manage resources as efficiently as possible. While ensuring that production goals are achieved, essential scheduling techniques like job order scheduling and machine loading allow for the effortless integration of maintenance tasks. Furthermore, by enhancing work priority and resource management, Critical Path Method (CPM) software reduces the possibility of delays and equipment breakdowns.

In CNC machine maintenance Effective scheduling is important for preserving high performance levels and ensuring machine durability in CNC machine maintenance. Predictive maintenance strategies, which leverage data analytics and condition monitoring, allow manufacturers to detect potential issues before failures occur (Smith & Brown, 2021). CNC machines operate more effectively, and maintenance is reduced when predictive maintenance is integrated into scheduling. Moreover, structured scheduling improves CNC machine reliability by aligning preventive maintenance activities with low-production periods, reducing operational disruptions, and enhancing overall productivity (Jones et al., 2020).

An effective demand forecast, resource availability, and adaptability to unexpected developments are required for a successful production schedule. To guarantee that equipment is maintained without affecting productivity, it must match production objectives with maintenance requirements. By including predictive and preventive maintenance in the schedule, unexpected equipment failures may be avoided, which lowers downtime and improves productivity. To avoid delays and lack of resources, manufacturing, maintenance, and inventory teams must communicate clearly with one another. Furthermore, producers may make flexible schedule adjustments through real-time monitoring and data-driven decision making, which improves overall operational efficiency and provides efficient production procedures.

Maintenance of Scheduling

-

-

Job description of Maintenance Engineer - Roles, Responsibilities & Skills

-

-

Answer all questions

-