4.0 PRODUCTIVITY & COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEMS (CMMS)

Section outline

-

EFFECTIVE MANUFACTURING SCHEDULING

-

COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEMS (CMMS)

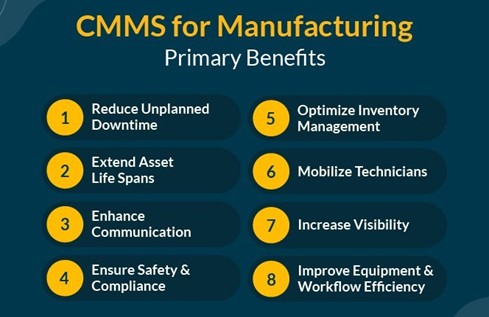

Computerized Maintenance Management Systems (CMMS) are required to increase the industrial sector's maintenance efficiency. By automating work order management, inventory monitoring, and maintenance scheduling, CMMS makes sure that equipment continues to remain in top shape. CMMS helps decrease unexpected breakdowns, eliminate downtime, and increase the lifespan of equipment by combining predictive and preventative maintenance techniques. Furthermore, capabilities like real-time reporting, safety tracking, and inventory management improve operational efficiency by enabling manufacturers to optimize maintenance procedures and make data-driven choices.

CMMS is essential for preserving quality and machine reliability in CNC machining. Since CNC machines need to operate with high precision and reliability, CMMS supports tracking maintenance tasks, maintaining updates on wear patterns, and scheduling preventative maintenance using real-time data. In order to identify possible faults before they occur, CMMS incorporates predictive maintenance techniques, including vibration analysis and heat monitoring. Furthermore, CMMS promotes the management of spare parts, minimizes human error, and provides that maintenance procedures are not interfering with output. Cloud services, IoT sensors, and CMMS improve CNC machine efficiency, reduce expenses, and increase production output as manufacturing moves toward Industry 4.0.

CMMS for Manufacturing Industry.

-

Equipment Maintenance Management.

-

-